Industry News

How to choose right turning insert in CNC machining?

How to choose right turning insert in CNC machining?

There are many parameters to consider when choosing a turning insert.

Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining performance.

Select insert geometry based on selected operation, for example finishing

Select the largest possible nose angle on the insert for strength and economy

Select the insert size depending on the depth of cut

Select the largest possible nose radius for insert strength

Select a smaller nose radius if there is a tendency for vibration

l = cutting edge length (insert size) RE = nose radius Nose angle

Turning insert geometry

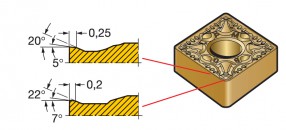

Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing operations. The diagram shows the working area for each geometry based on acceptable chip breaking in relation to feed and depth of cut.

Roughing

High depth of cut and feed rate combinations. Operations requiring the highest edge security.

Medium

Medium operations to light roughing. Wide range of depth of cut and feed rate combinations.

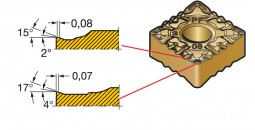

Finishing

Operations at light depths of cut and low feed rates. Operations requiring low cutting forces.

QUOTED FROM: SANDIVIK

If you want more CNC cutting information,pls dont hesitate come and email us :info@chinacarbideinserts.com

Welcome all the people who dedicated in metal cutting field.

Categories

Latest News

Contact Us

Contact: Jennifer

Tel: +86-731-22481009

Fax: 0731-22481019

Email: jennifer@lctcarbide.com

Add: D3-05 Automotive Component Park, No. 1986 Taishan Road Zhuzhou, Hunan, China